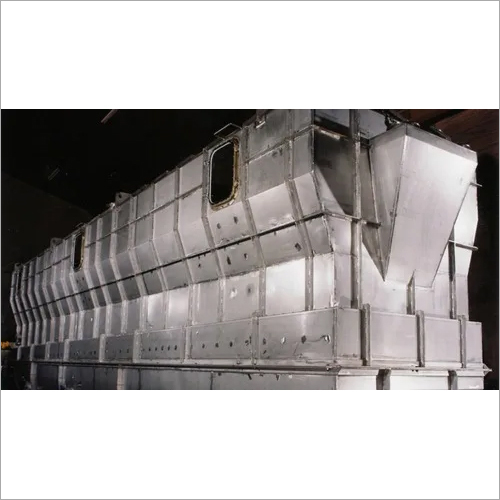

Continuous Fluid Bed Dryer

Product Details:

- Fuel Type Electrical / Gas / Steam

- Heat Source Electric / Steam / Gas

- Power Consumption Depends on capacity and configuration

- Material Stainless Steel (304/316) / Mild Steel

- Temperature Up to 120C

- Technology Continuous Fluidization Drying

- Dimension (L*W*H) Customizable as per requirement

- Click to View more

Continuous Fluid Bed Dryer Price And Quantity

- 1 Unit

Continuous Fluid Bed Dryer Product Specifications

- Continuous Fluidization Drying

- Electric / Steam / Gas

- Electrical / Gas / Steam

- Customizable as per requirement

- Depends on capacity and configuration

- Stainless Steel (304/316) / Mild Steel

- Up to 120C

Continuous Fluid Bed Dryer Trade Information

- 1 Unit Per Month

- 3-4 Week

Product Description

With our wide industrial experience, we are engaged in providing a wide range of quality approved range of Rotary Fluid Bed Dryer. These dryers are considered ideal for constant and falling rate drying. Designed using advanced technologies, these dryers are working on the principle of phenomenon that solid materials with well-defined particle size distributions act as liquid when fluidized by air. These dryers are widely used for powdered materials and granules with average size of 50 - 2000 microns. Furthermore, we are offering these Rotary Fluid Bed Drying Plant within promised time frame.Features Of Rotary Fluid Bed Dryer:

- Rust-free

- Easy operation

- Long service life

- Perfect finish

Fluid Bed Drying has many advantages compared with other drying techniques and equipotent available in the market. These are widely demanded for their constant and falling rate drying methodology.

Our dryers work on the phenomenon that solids materials with a well defined particle size distribution behave as liquid when fluidized by air. Residual moisture can be reduced by preheating the air.

Fluid Bed Dryer is used for drying for powder and granules of average particle size 50-2000 microns. Vibro Fluid Bed Dryer helps the movement of solids and drying process.

Our company is a well known supplier of Fluid Bed Drying Plant, which is used for fluidization of materials.

These materials are characterized by following physical properties:

- Wide particle size distribution

- Low strength of wet or dry particles

- Stickiness or thermo plasticity of the particles

- Pasty properties of the wet feed

In a vibrated fluid bed drying plant, material can be easily transported with the combined effect of fluidization and vibration. Fluidization velocity can be selected as per need for minimizing the smaller particles. This is also effective in avoiding gas bubbling in the fluid bed hence minimizes attrition. In addition to this, residence time can be adjusted easily by vhanging the bed height, through the overflow weir position. Furthermore, there is option for a cooling section by partitioning of the plenum chamber.

Typical products handled:

- Salt

- Milk products (used as a secondary dyer)

- Chemicals

- Tea

Fluid Bed Dryers can be designed as the application in which is used and are clasified as direct or indirect (air heating method) and +co-current or counter current (material air contat).

The material to be dried i uniformly dispersed over the entire cross-section, by use of internals designed based on the material properties. Heated ar then passes through the falling material, resulting in uniform drying. The Seals are provided at the ends to ensure minimum air leakage.

The advantages of rotary dryers are:

- Cost effective

- Minimal maintenance cost

- Ideal for high volumes

- High thermal efficiency

Typical products handled using this dryer:

- Sand

- Coal

- Ores

- Maize germs

- Clays

- Industrial sludges

Specification Of Rotary Fluid Bed Dryer:

- Material : Stainless Steel

- Power : 30 kW

- Phase : Three Phase

- Frequency : 50 Hz

- Voltage : 415 V

- Speed : 2800 RPM

- Max Temperature : 35 -80 Celsius

- Grade : Automatic

- Design : Standard

Advanced Drying Technology for Critical Industries

Our Continuous Fluid Bed Dryer utilizes state-of-the-art fluidization technology, enabling uniform drying of bulk materials by suspending particles over a stream of hot air. This approach enhances efficiency, preserves product quality, and significantly reduces drying times. The dryers design is suitable for sensitive applications in pharmaceuticals, food processing, chemicals, and agricultural products, where consistency and hygiene are paramount.

Intelligent Control and Safety Features

Equipped with a PLC-based automation system, the dryer offers seamless, adjustable operation and optimal process management. Robust safety mechanisms including overheat protection, emergency stop, and noise control (below 80 dB) ensure a reliable and user-friendly experience. The systems adaptability allows precise tuning of air flow rates and temperatures up to 120C, guaranteeing superior moisture removal and product safety.

Customizable and Durable Construction

Fabricated from high-quality stainless steel (304/316) or mild steel, this fluid bed dryer is available in mirror or matt finishes and features perforated trays for even air distribution. Dimensions and configurations can be customized to meet specific site requirements. The use of modular components, along with easy-clean design, supports operational efficiency and long-term durability.

FAQs of Continuous Fluid Bed Dryer:

Q: How does the Continuous Fluid Bed Dryer achieve uniform drying?

A: The dryer utilizes a fluidization process, where hot air flows upward through perforated stainless steel trays, suspending the product and ensuring every particle is evenly exposed to heat. This method results in consistent and uniform drying across the entire batch, regardless of capacity or product type.Q: What types of products can be processed with this dryer?

A: This dryer is suitable for a broad range of applications, including pharmaceuticals, food ingredients, chemicals, as well as agricultural and allied products. Its flexibility stems from precise control systems and adjustable air flow rates, making it ideal for dry powders, granules, and heat-sensitive materials.Q: When should I choose a continuous fluid bed dryer over other drying technologies?

A: Opt for a continuous fluid bed dryer when you require high-efficiency, uniform drying and seamless, automated operation. It is especially beneficial for industries needing consistent product quality, rapid processing, and energy-efficient moisture removal for large-scale production.Q: Where can this dryer be installed and how is it customized?

A: The dryer can be installed in industrial settings such as pharmaceutical plants, food processing units, and chemical factories. Its dimensions and configurations can be tailored to match specific site layouts and production needs, ensuring optimal integration into existing workflows.Q: What benefits do PLC-based automation and safety features offer?

A: PLC-based automation facilitates precise control over temperature, air flow, and discharge, enabling efficient, hands-free operation. Advanced safety features such as overheat protection and an emergency stop enhance user safety and ensure stable, reliable performance, minimizing process downtime.Q: How is energy used and what are the available heat sources for this dryer?

A: Energy use depends on the dryers capacity and chosen configuration. The system can operate using electrical, gas, or steam heating, allowing adaptability to available utilities. Its efficient design optimizes energy consumption, contributing to reduced operational costs and environmental impact.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese